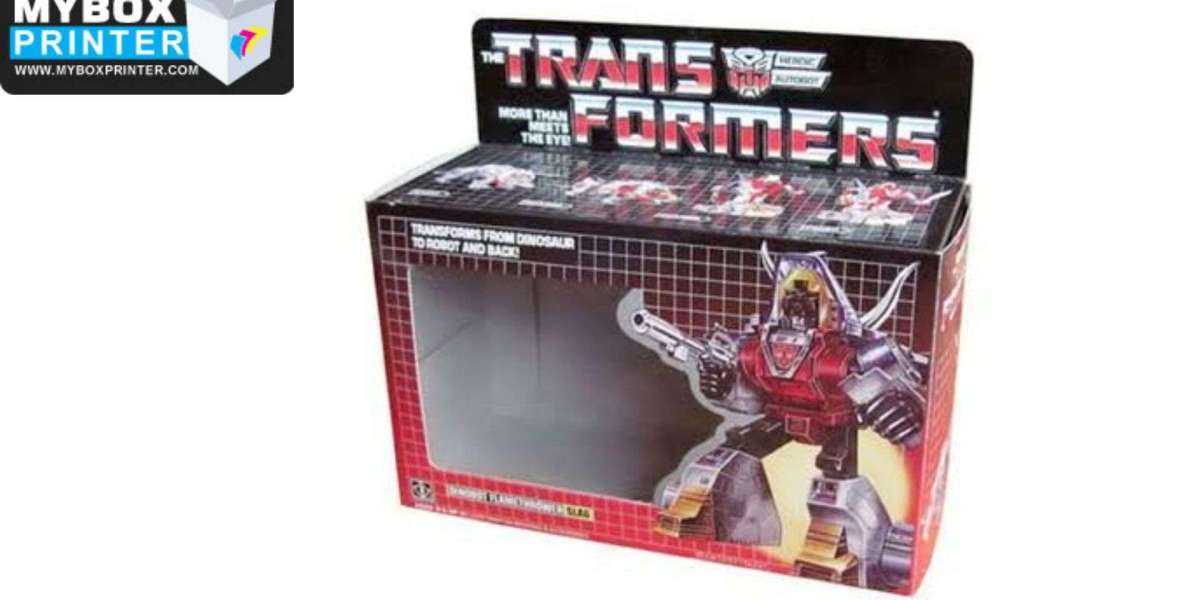

In the aggressive international of retail, status out on the cabinets is critical for toy manufacturers. Custom packaging plays a pivotal function in catching the attention of customers and communicating the essence of the product inside. Among the numerous varieties of packaging available, custom window toy packaging bins have become increasingly more popular because of their ability to showcase the product whilst supplying essential safety. In this comprehensive manual, we will delve into the world of custom toy packaging containers, exploring their advantages, layout issues, production method, and environmental effect.

Benefits of Custom Window Toy Packaging Boxes

1. Visibility: The number one advantage of window toy packaging is the visibility it gives. By supplying a clean view of the real toy inside, it permits clients to see the product without starting the box. This transparency builds trust and encourages buy choices.

2. Enhanced Marketing: Custom window boxes provide a canvas for innovative advertising. Manufacturers can print branding factors, trademarks, and product info at the field at the same time as still showcasing the toy. This combination of facts and visibility is an effective advertising device.

3. Protection: Despite the open window, these packing containers offer ok protection to the toy internal. The window is commonly made from a long lasting, transparent cloth which includes PET or PVC, ensuring the toy remains secure from dirt, dirt, and coping with throughout transit and display.

4. Differentiation: In a crowded market, specific packaging sets a brand aside. Custom window toy packaging lets in for limitless customization options, from shape and size to the placement of the window. This specialty allows toys to stand out and be memorable to consumers.

5. Consumer Experience: Opening a toy boxes in a custom window field can be an enjoy in itself. The anticipation of seeing the toy thru the window adds exhilaration and engagement, improving the general purchaser experience.

Design Considerations for Custom Window Toy Packaging Boxes

When designing custom toy packaging boxes, several elements should be considered to ensure the field isn't always simplest visually appealing however also purposeful and sensible.

1. Window Placement: The placement of the window is important. It should align with the toy's most appealing features, allowing customers to see the important elements of the product. For example, a doll's face, a vehicle's tricky layout, or a puzzle's colorful pieces.

2. Size and Shape: The size and shape of the field ought to supplement the toy internal. A cushy match prevents the toy from shifting for the duration of shipping and complements the overall presentation. However, there need to be enough area to without difficulty take away the toy without destructive the packaging.

3. Material Selection: The choice of materials affects both the aesthetics and sustainability of the packaging. Opt for green alternatives together with recyclable cardboard or biodegradable plastics for a more sustainable packaging answer.

4. Branding Elements: Incorporating branding elements like emblems, hues, and taglines is important for logo popularity. These factors must be outstanding but not overshadow the visibility of the toy via the window.

5. Safety Standards: Ensure that the packaging meets safety standards, particularly if the toy is supposed for kids. Rounded edges, non-poisonous materials, and proper air flow are crucial concerns.

Manufacturing Process of Custom Window Toy Packaging Boxes

The manufacturing method of toy boxes wholesale includes several steps to make sure a remarkable give up product.

1. Design and Prototyping: The manner starts off evolved with the advent of a layout based at the toy's dimensions and branding necessities. Prototyping permits for checking out the design before full manufacturing, making sure everything fits perfectly.

2. Material Selection: Once the layout is finalized, the right substances are selected. This consists of deciding on the sort of cardboard for the field, as well as the obvious material for the window.

3. Printing: Printing provides the branding factors, product details, and any decorative elements to the packaging. Advanced printing techniques like offset or digital printing can acquire vibrant shades and elaborate designs.

4. Die-Cutting: The cardboard is then die-cut into the particular shape and size of the container. Precision is vital to ensure the window aligns perfectly with the toy inside.

5. Window Insertion: The obvious window cloth, frequently PET or PVC, is then inserted into the die-cut window place. This is done with precision to create a continuing and secure window.

6. Folding and Assembly: The cardboard is folded along the creases and assembled into the very last container form. Adhesives or tabs are used to steady the edges, creating a robust structure.

7. Quality Control: Each field undergoes rigorous pleasant manipulate checks to ensure it meets the design specs. This consists of checking for correct window placement, printing first-rate, and structural integrity.

Environmental Impact and Sustainability

In current years, there has been a growing consciousness on sustainability in packaging. Toy producers are an increasing number of choosing green materials and practices to lessen their environmental footprint.

1. Recyclable Materials: Many custom window toy packaging packing containers are made from recyclable materials together with cardboard and paperboard. After use, these boxes may be recycled, lowering waste dispatched to landfills.

2. Biodegradable Plastics: Some transparent window materials at the moment are to be had in biodegradable options. These materials ruin down greater fast within the surroundings, reducing their effect on ecosystems.

3. Reduced Packaging: Efficient layout can also cause reduced typical packaging fabric utilization. Designing packing containers that in shape the toy snugly reduces the want for excess fabric, promoting sustainability.

4. Consumer Education: Including messaging on the packaging approximately recycling and accountable disposal can inspire consumers to make environmentally conscious choices.

5. Regulatory Compliance: Toy manufacturers must follow environmental rules regarding packaging materials. Staying informed approximately those guidelines guarantees accountable sourcing and disposal practices.

Conclusion

Custom window toy packaging packing containers offer a mess of advantages, from improved visibility and marketing to protection and sustainability. By carefully thinking about design elements, substances, and manufacturing strategies, toy manufacturers can create packaging that now not simplest showcases their merchandise however additionally aligns with cutting-edge environmental requirements. As purchaser options shift in the direction of eco-conscious alternatives, adopting sustainable practices in packaging becomes no longer just a fashion, however a need for the industry. By investing in custom toy packaging, producers can raise their brand, enhance purchaser experience, and contribute to a greener destiny.