Why is it called rapid prototyping? And how can it revolutionize your approach to product development? Buckle up, intrepid design explorers, for this in-depth blog dives deep into the fascinating world of rapid prototyping, unveiling its historical roots, dissecting its core principles, and showcasing its transformative power across diverse industries. So, grab your virtual tools, unleash your creativity, and prepare to embark on a journey where speed meets innovation, paving the way for faster, better, and more successful product development.

Read More @ https://bit.ly/3xn3XIn

Laying the Foundation: Exploring the Design Landscape

Before delving into the rapid prototyping phenomenon, let’s establish a firm footing:

Product Design: The process of creating a new product, encompassing ideation, sketching, prototyping, testing, and refinement. Imagine it as a grand journey from a seed of an idea to a thriving product, navigating through diverse terrains and overcoming challenges along the way.

Prototyping: Building a tangible or virtual representation of a design concept to test its functionality, aesthetics, and user experience. Think of it as constructing a miniature model of your final product, allowing you to experiment, visualize, and refine your vision before committing to full-scale production.

Traditional Prototyping: The classic approach, often relying on manual techniques like sculpting, model making, and physical mockups. Imagine crafting your product miniature with traditional tools and materials, testing it with your hands and engaging with it through physical interactions.

Digital Prototyping: The modern counterpart, utilizing computer-aided design (CAD) software, 3D printing, and other digital tools to create virtual or physical prototypes. Imagine building your product model using virtual blocks and simulated environments, testing its functionalities and user interactions within the digital realm.

The Roots of Speed: Unraveling the History of Rapid Prototyping

The term “rapid prototyping” emerged in the late 1980s as a response to the growing need for faster design iterations and reduced time-to-market. Previously, prototyping was a slow and expensive affair, often hindering innovation and agility. However, advancements in 3D printing, CAD software, and other technologies paved the way for a paradigm shift. Designers could now create functional and visually appealing prototypes in hours or days, instead of weeks or months. This dramatic reduction in development time unlocked a new era of experimental design, iterative refinement, and accelerated innovation.

The Pillars of Speed: Unveiling the Core Principles of Rapid Prototyping

So, what makes rapid prototyping so… rapid? It all boils down to several core principles:

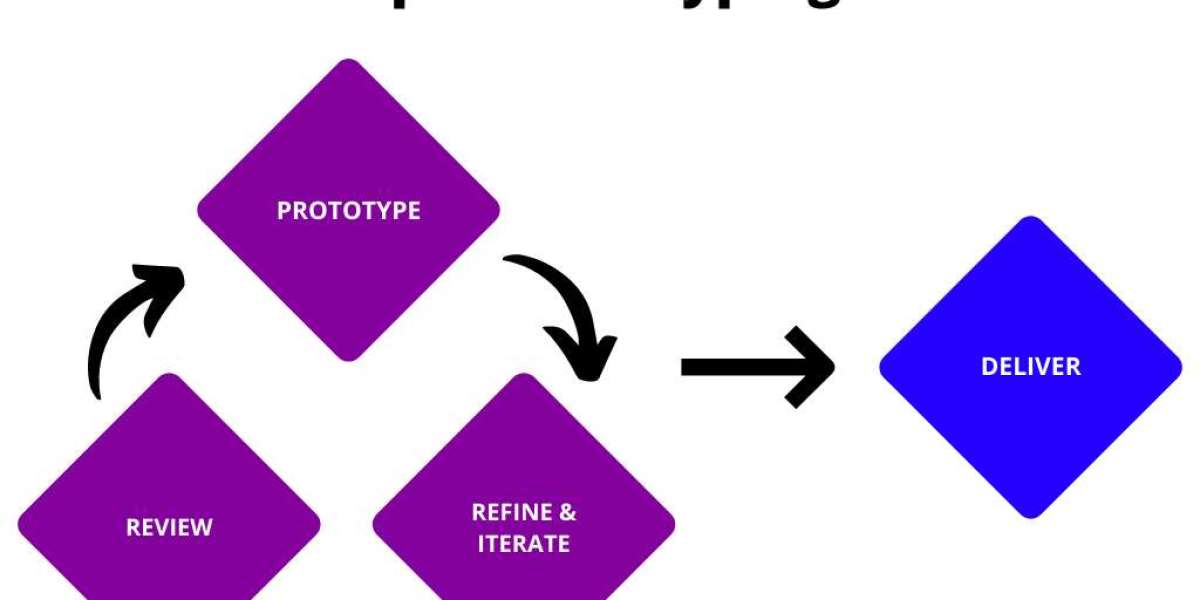

Focus on Iteration: Rapid prototyping prioritizes building multiple prototypes quickly, allowing for frequent testing and feedback loops. Imagine constructing several smaller versions of your product model, testing each one with users and iterating based on their insights.

Reduced Fidelity: Rapid prototypes often prioritize functionality and usability over high-fidelity aesthetics. Think of rough sketches or basic 3D models, focusing on core functionalities and user interactions rather than intricate details and polished finishes.

Embrace Failure: Rapid prototyping encourages a “fail fast, learn fast” mentality. View early prototypes as learning tools and accept them as potentially flawed and incomplete. Imagine embracing the lessons learned from each “broken” model, refining your design based on the failures and moving closer to success.

Leverage Technology: Utilize advanced tools like CAD software, 3D printing, and rapid manufacturing technologies to streamline the prototyping process. Imagine employing digital sculpting tools and fast-printing machines to build your product models quickly and efficiently.

Real-World Engines of Innovation: Witnessing Rapid Prototyping in Action

Let’s see how these principles translate into tangible results across diverse industries:

Automotive Industry: Rapid prototyping allows car designers to test different shapes, ergonomics, and features of a new car model quickly and affordably, leading to faster development cycles and improved user experiences. Imagine crafting miniature car models, testing them in virtual wind tunnels and user simulations, before refining the final design and hitting the production line.

Medical Devices: Rapid prototyping empowers engineers to create functional prototypes of medical devices, enabling them to test their effectiveness and usability in simulated environments before involving human subjects. Imagine building miniature models of surgical tools or prosthetic limbs, testing their functionalities and interactions with virtual patients, before bringing them to life for real-world use.

Aerospace Engineering: Rapid prototyping allows aerospace engineers to test wing designs, rocket components, and spacecraft structures through physical and virtual prototypes, optimizing performance and ensuring safety before launch. Imagine crafting miniature drones or wind tunnel models of spacecraft, analyzing their behavior in simulated environments and refining them before they ascend into the vast expanse of space.

Consumer Products: From smartphone cases to kitchen gadgets, rapid prototyping empowers product designers to quickly iterate on form factors, user interfaces, and features, leading to more user-centric and commercially successful products. Imagine building rough models of your next phone design, holding them in your hands, and gauging user reactions before finalizing the sleek device you hold in your palm today.

Overcoming the Speed Bumps: Navigating the Challenges of Rapid Prototyping

While rapid prototyping promises to turbocharge the design process, it’s not without its challenges:

Misaligned Expectations: Setting unrealistic expectations regarding prototype fidelity and functionality can lead to disappointment and hinder progress. Remember, these are rough models, not finished products; focus on core principles and iterate towards perfection.

Technical Expertise: Some technologies like 3D printing require specific skills and knowledge. Invest in training or collaborate with specialists to ensure efficient utilization of these tools.

Resource Management: Rapid prototyping can be resource-intensive, particularly with high-tech methods. Plan your budget carefully and prioritize resources towards critical prototypes and functionalities.

Scope Creep: The rapid iteration loop can lead to uncontrolled feature additions and design deviations. Clearly define project scope and maintain focus on core objectives to avoid mission creep.

A Call to Action: Fueling Innovation with Rapid Prototyping

Mastering rapid prototyping isn’t just about building fast; it’s about embracing a mindset of agility, adaptability, and continuous learning. Here’s how it can transform your approach to design:

Boost Design Efficiency: Reduce development time and cost by refining ideas through rapid iteration and early testing. Imagine streamlining your design journey, avoiding costly detours and reaching your destination faster with valuable insights in hand.

Enhance User Experience: Prioritize user-centric design by gathering real-time feedback from prototypes and incorporating it into your final product. Imagine building your product alongside your users, shaping it around their needs and preferences for true satisfaction.

Reduce Risk and Uncertainty: Test and refine your design concepts early to identify potential flaws and mitigate risks before committing to full-scale production. Imagine deactivating potential bombs before they explode, identifying and resolving issues in the prototype stage for a smoother launch and a more successful product.

Foster a Culture of Innovation: Encourage experimentation, embrace failure as a learning opportunity, and celebrate rapid iteration within your team. Imagine transforming your design landscape into a fertile ground for creative exploration, where ideas germinate and flourish at lightning speed.

Join the movement, unleash the power of rapid prototyping in your design process, and embark on a journey where speed meets ingenuity. Remember, the path to innovation isn’t a single, slow lane; it’s a winding, multi-lane highway open to those who dare to accelerate, iterate, and learn with every turn. So, buckle up, hit the gas pedal of creativity, and embrace the exhilarating race towards breakthrough products and a future fueled by rapid design evolution.

You may be interested in:

Rapid Prototyping: Unleashing Innovation at the Speed of Thought

Rapid Application Development: Accelerating Your Digital Solutions

The Future of Machines: Trends and Predictions

SAP CLOUD APPLICATION STUDIO Pilot debugging issue

About SoftAt PVT. LTD. :

We are a new generation IT company, focused on enterprise software implementation & Support Services.To accomplish the sustainable growth of a business, the essential factor is the industry-specific solutions that adapt to the system and its necessity. For this, SoftAt is the best place to get the Righteous solution for your business.With nearly two decades of 15 years of experience in SAP Implementation, SAP up-gradation, and SAP migration, we at SoftAt work to empower businesses with our SAP & Oracle solutions.

Contact Us: -

SoftAt Private Limited

No. A01 Second Floor Upon Bank of Baroda Kharadi,

Kharadi-Hadapsar Road, Infront of HP Petrol Pump,

Thite Vasti, Kharadi,

Pune, Maharashtra-411014

India: +91-7796611155

Email: – [email protected]